FOR MANUFACTURING INDUSTRY

Logivision, the solution for your production with zero defects

Artificial Vision and Edge Computing to improve and automate quality control and ensure the production chain.

BENEFITS

Logivision enables manufacturers to improve production from minute zero

AUTOMATE YOUR QUALITY CONTROL

REVIEW 100% OF THE PRODUCT

ELIMINATE QUALITY WALLS

REDUCES DEFECTS RECEIVED BY THE CUSTOMER

CHARACTERISTICS

Manufacture with the peace of mind that everything is going smoothly

EFFICIENT

Process and filter data with AI, saving in information systems only the data that interests you, such as defective parts or statistics.

FAST

Fast response thanks to local AI processing with Edge technology. Instant response compared to cloud applications.

INTEGRABLE

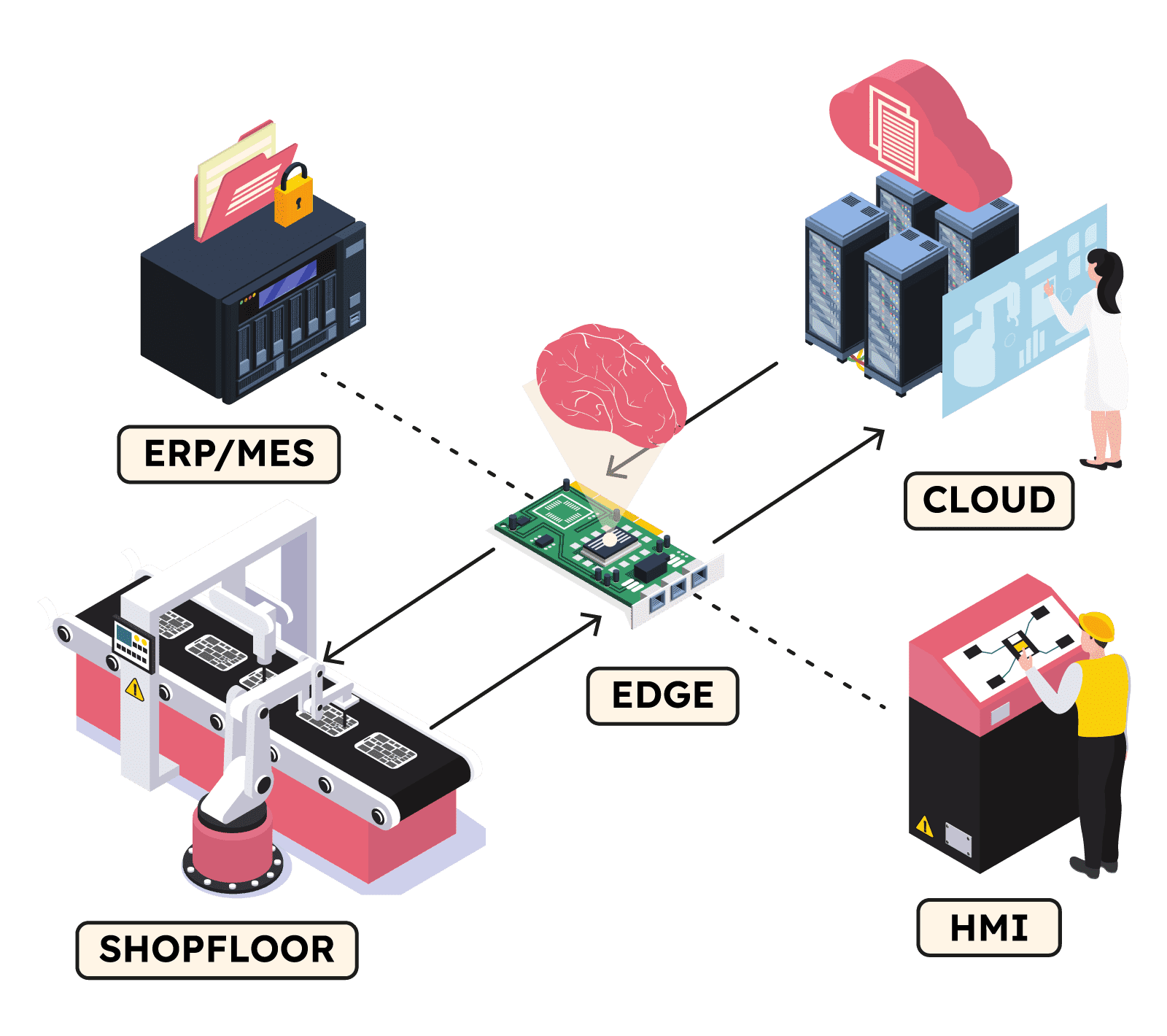

Logivision easily integrates with existing infrastructure with both industrial protocols such as Profinet and OPC-UA, as well as MES, ERP and cloud systems.

HISTORY VIEWING

The images and results of AI processing (defects, etc.) are stored in a database for subsequent analysis.

FLEXIBLE

Logivision uses flexible image processing technology developed by Logicmelt, which allows it to be adapted to the client’s specific problem in minutes. Logivision supports almost any type of camera and camera configuration.

APPLICATION AREAS

Logivision is applicable to a multitude of areas of the company throughout the entire value chain

QUALITY

Defect detection, component counting…

PRODUCTION

Helps the operator and detects human errors.

MAINTENANCE

Detection of abnormal situations in a machine.

SECURITY

Detection of PPE and access to dangerous areas.

HOW WE DO IT

A flexible platform that adapts to your needs and problems

CAPTURE WITH ONE OR MORE CAMERAS

AI PROCESSING AT THE EDGE

VIEWING IMAGES AND DETECTIONS

1.

One or several cameras capture images of the production process, machines or operators. Logivision supports industrial cameras, thermal cameras, 3D cameras and video surveillance cameras.

2.

The Edge system processes the images and performs detections on them, such as defects. Its size, position, number and type can be measured. Logicmelt uses small, easy-to-install embedded Edge systems.

3.

Images and detections are available through the Logivision operator terminal, which gives access to real-time data and historical data. Logivision supports multiple terminals accessing data at the same time.

4.

Depending on the problem and the result extracted by the AI, a warning is generated for the operator or the production line is stopped. The Edge system can be connected directly to the PLC type line control computer through OPC-UA or industrial protocols such as Profinet.

THE NEW ERA OF QUALITY CONTROL

Advantages of using Edge Technology in combination with Cloud.

LOW LATENCY

The Edge processes AI locally, enabling control applications to be carried out in real time and notifying operators instantly.

SECURITY

If the communications network fails, the systems continue working in isolation locally and recover the connection when it is available again.

NETWORK DECONGESTION

Since processing is local, only the most important data is sent to information systems, such as ERP or cloud, through the network.

PRIVACY

Sensitive images of the production process or operators are processed at the Edge and destroyed, sending only the AI results over the network, not the images.

COST SAVINGS

Processing images intensively is cheaper if done locally with Edge Technology than if done in the Cloud.

SERVICES FOR TECHNOLOGICAL COMPANIES

Let’s develop your product based on A.I. together

Our R&D services so that together we create your product with Artificial Intelligence.